This dissertation is submitted for the degree of Doctor of Philosophy at the University of Cambridge, and is an account of work carried out in the Department of Materials Science and Metallurgy from October 2002–2005 under the supervision of Professor H. K. D. H. Bhadeshia. This work is to the best of my knowledge original, except where acknowledgement and reference is made to previous work. Neither this, or any substantially similar dissertation has been or is being submitted for any degree, diploma or other qualification at this, or any other university. This dissertation contains less than sixty thousand words.

Parts of this thesis have been published previously in journals, much of Chapter 5 has been published in “Three-Dimensional Atom Probe Analysis of Carbon Distribution in Low-Temperature Bainite” by Peet, Babu, Miller and Bhadeshia [1]. Chapter 6 presents results from two alloys, the results of one have been presented in “Tempering of a Hard Mixture of Bainitic Ferrite and Austenite” by Garcia–Mateo, Peet, Caballero and Bhadeshia [2].

I gratefully acknowledge the Engineering and Physical Sciences Research Council, Corus Plc (now Tata Steel Europe Ltd), the Isaac Newton Trust for funding my study and the Worshipful Company of Iron Mongers and the Shared Research Equipment (SHaRE) User Facility at Oak Ridge, which enabled me undertake atom probe studies presented in this thesis. I am grateful to Prof. D. J. Frey and Prof. A. L. Greer for the provision of laboratory facilities in the Department of Materials Science and Metallurgy.

Many thanks to all the friends and colleagues in the phase transformations and complex properties group for their friendship. Special thanks to Miguel Angel Yescas-Gonzalez, Shingo Yamasaki, Kazukuni Hase, Teruhisa Okumara, Mohamed Sherif, Saurabh Kundu, Carlos Garcia–Mateo, Thomas Sourmail, and Rose Yan for their useful advice and discussion which aided the work presented here.

It gives me pleasure to thank Mary Vickers, David Vowles and David Nicol who provided much useful assistance and advice for X–ray diffraction, scanning electron microscopy and transmission electron microscopy, and Harald Dobberstein and Jon Rickard in the Cavendish Laboratory for their assistance in the use of the focused ion beam microscope. Without Mike Miller, Kay Russel and Suresh Babu the atom probe work would not have been possible. I would also like to thank Marimuthu Murugananth for his friendship and assistance during my visit to Oak Ridge. Thanks to Kevin Roberts and to Brian Whitemore for their assistance with various experiments.

I also would like to thank all who have contributed to open software used to prepare this thesis, especially the developers of the Linux kernel, gcc, g77, gfortran, Debian, Redhat, Gnome, vi, Gnuplot, xfig, Gimp, inkscape and LATEX.

I am greatly indebted to Prof. Harshad Kumar Dharamshi Hansraj Bhadeshia for his guidance, advice, enthusiasm and patience.

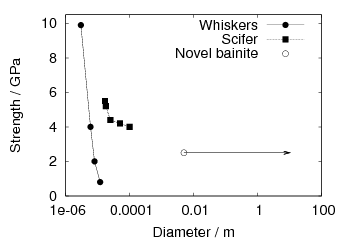

This thesis concerns a special class of novel bainitic steels, which can transform to bainite at around 200∘C. The microstructure has been labelled ‘super–bainite’, a mixture of fine bainite plates (20-40 nm thickness) in a matrix of austenite which is highly enriched in carbon. These high strength steels have found application as armour plate, and there has been further research to utilise them for aerospace applications.

The introductory chapter of the thesis contains a literature survey, starting from general background describing the solid–state transformations, and then developing with particular reference to earlier work on bainite, carbide–free bainitic steels, and on this new class of low–temperature bainitic steels.

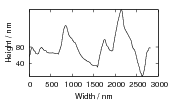

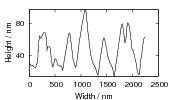

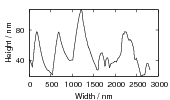

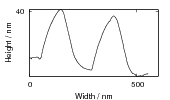

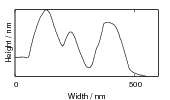

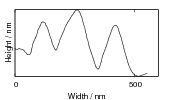

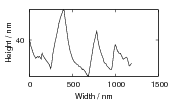

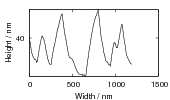

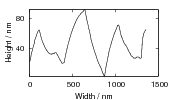

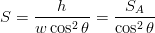

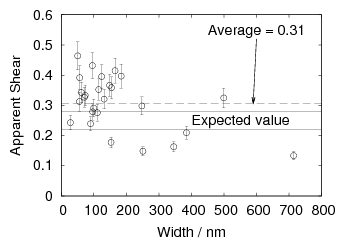

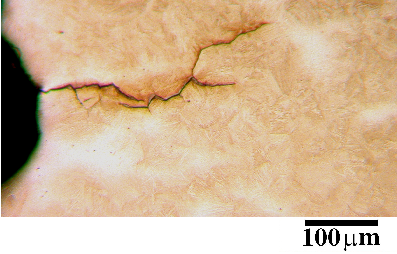

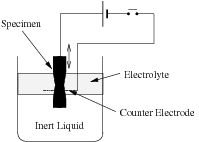

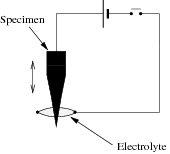

Bainite transforms by a displacive mechanism, and chapter 2 characterises the surface relief due to transformation using a high–resolution surface technique. The measured shear component is larger than expected from past experience. This large shear component is consistent with the slender aspect of the ferrite plates. It may be that the small size of the features makes it much more difficult to measure the shear component as compared to transformation at higher temperatures.

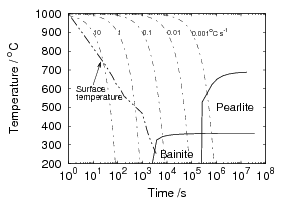

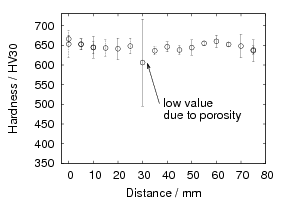

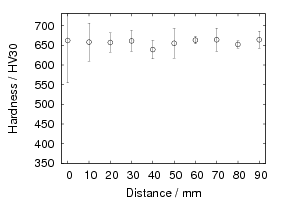

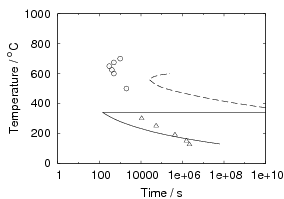

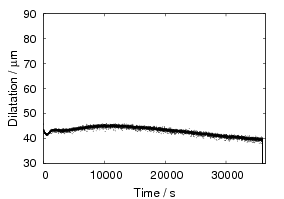

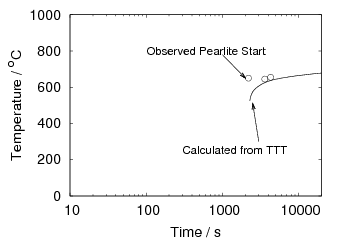

Since the strengthening mechanism is a result of transformation, these steels offer a unique opportunity to achieve high strengths in large section sizes. In chapter 3 results of transformation of large samples are reported and experimental results are compared against calculated continuous cooling curves. It is demonstrated that uniform transformation of bulk sections is possible, and methods are presented that can be used to estimate limiting section sizes from the calculated time–temperature–transformation curves. It was found that in the alloy studied, the isothermal transformation kinetics were faster than calculated. It is proposed that this may be due to the formation of pro–eutectoid cementite.

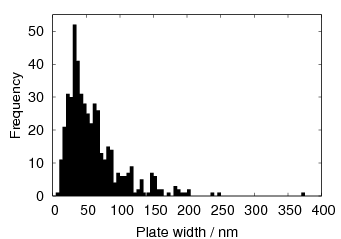

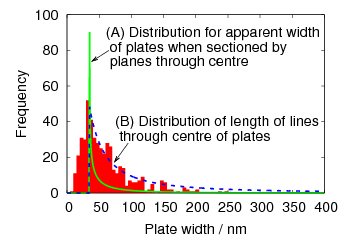

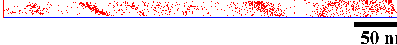

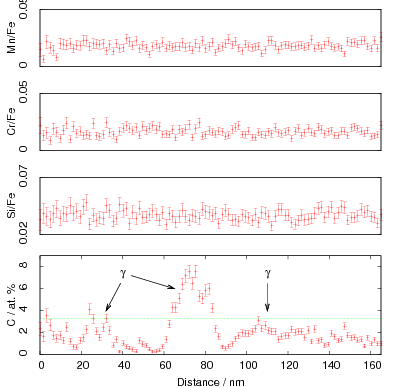

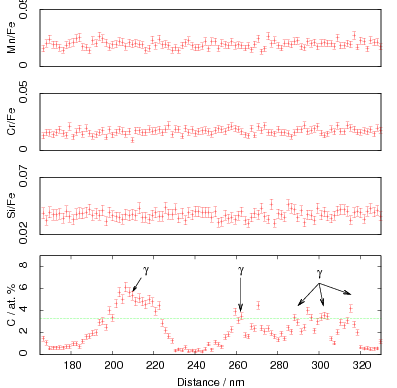

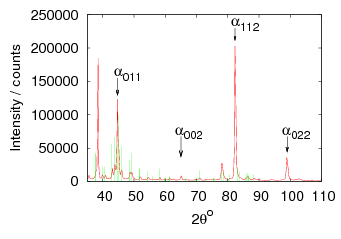

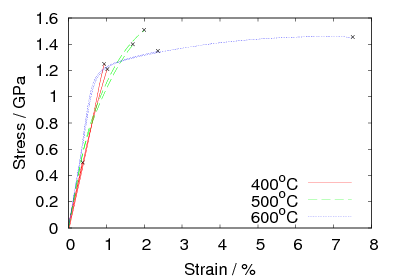

The microstructure due to transformation at 150 and 200∘C was characterised by X–ray diffraction, hardness testing, and thin–foil electron microscopy as presented in chapter 4. The bainite plates size was determined to be 39±1 nm after transformation at 200∘C but unexpectedly increased upon transformation at 150∘C. As previously reported, significant carbon supersaturation occurred in the austenite by transformation at 200∘C as limited by free–energy change to super–saturated bainite, however no enrichment could be measured in the austenite transformed at 150∘C. This indicates that there is a optimum temperature for achieving both fine plate size, and stabilisation of retained austenite. The microstructure as a result of transformation at 200∘C was characterised by atom probe tomography (chapter 5). These direct measurements of carbon content are in agreement with the X–ray diffraction data reported in chapter 4. It can also be confirmed that substitutional element partitioning does not occur from the bainitic ferrite during transformation. The results are fully consistent with the displacive nature of the transformation.

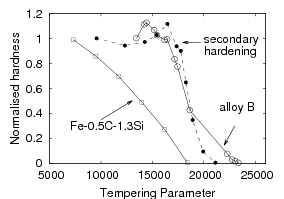

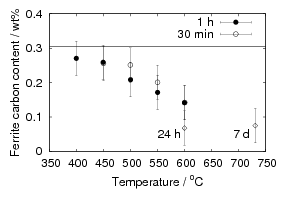

The final two chapters of results deal with tempering of low–temperature bainite. The loss of hardness is consistent with the major strengthening mechanism being due to the plate size. X–ray measurements show that carbon in ferrite slowly reduces with increasing temperature, along with the recovery of heterogeneous strains. In contrast, hardness drops more rapidly after some critical temperature is reached. Carbides were identified by both X–ray diffraction of extracted residues, and using atom probe tomography, to be cementite. Tempering for 30 min at 400 and 500∘C resulted in a fine carbide size around 10 nm, which can also contribute to strengthening, as well as being ideally positioned to prevent coarsening of the ferrite. Austenite decomposition takes some time, and a small amount can be retained even at 500∘C for 15 minutes, or at 450∘C for 1 h.

The final chapter deals with general conclusions and proposes future directions of research based on the results. Further work is needed to fully characterise the tempering behaviour of these steels, particularly at lower tempering temperatures which may be relevant in some applications.

Novel high–carbon high–silicon steels have been developed by Caballero et al. [3]. The alloying of these steels allows a bainitic microstructure to form at unconventionally low temperatures. The resultant fine bainitic ferrite plates contribute significantly to the hardness and strength [3, 4].

Refinement of microstructure by transformation is an extremely attractive strengthening mechanism, introducing obstacles to dislocation movement, but unlike other strengthening mechanisms, not necessarily leading to a reduction in toughness [5]. Using transformation rather than deformation to introduce defects means that even large sections can be hardened.

These steels are a development of silicon–containing carbide–free bainitic steels. Silicon additions are known to prevent the formation of embrittling carbides during the bainite transformation [6, 7]. This results in a microstructure of plates of bainitic ferrite in a matrix of carbon enriched retained austenite1 . One advantage is the suppression of coarse carbides which can limit the toughness. The retention of austenite can also have a profound effect on the mechanical properties.

Alloying with silicon is also known to decrease the rate at which martensitic steels temper [8, 9]. Bainitic steels are more resistant to tempering than martensitic steels, because their strength is not predominantly due to supersaturation of carbon [10, 11]. Previous work on the high–carbon high–silicon steels shows that the microstructure can retain much of its high hardness upon tempering [3].

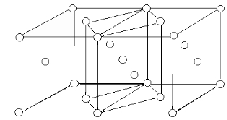

The susceptibility of iron to solid–state transformations between the two crystal structures which are stable at atmospheric pressure enables a huge variety of microstructures and mechanical properties to be generated in iron–based alloys by thermal treatments. These two structures are face–centred cubic (FCC) austenite and body–centred cubic (BCC) ferrite as illustrated in figure 1.1.

In pure iron the transition from ferrite to austenite and back to ferrite upon cooling and heating, is significantly influenced by magnetism. The energy difference between the two states is very small, and so alloying elements can have a large effect on the transition. Due to the industrial significance and scientific interest, many thermodynamic assessments have been made of iron–based systems so it is possible to model these effects by computation [12, 13].

Austenite is the stable form between 910 and 1390∘C in pure iron at atmospheric pressure. The face–centred cubic structure of austenite offers an optimum stacking in space for spheres, as first observed by Kepler [14] and recently proven by Hales [15]. Transformation from austenite to body–centred cubic ferrite is therefore inevitably accompanied by an increase in volume. Alloying elements can either substitute for an atom in the crystal lattice, or when the solute atoms are small enough they may occupy the interstitial sites between the larger solvent atoms. Carbon and nitrogen are relatively small and occupy interstitial sites in austenite and ferrite. Despite the greater packing efficiency the interstices in austenite are larger, resulting in higher solubilities. The volume increase when austenite transforms to ferrite is typically between 1 and 3% dependent on temperature, there are also significant differences in the solubility (table 1.1) and mobility of interstitial elements in austenite and ferrite. The diffusion coefficient at 910∘C being 1.5×10−7 cm2s−1 in austenite and 1.8×10−6 cm2s-1 in ferrite [16].

| Temperature /∘C | Solubility /wt% | Solubility /at.% | |

| C in γ–iron | 1150 | 2.04 | 8.8 |

| 723 | 0.80 | 3.6 | |

| C in α–iron | 723 | 0.02 | 0.095 |

| 20 | < 0.00005 | < 0.00012 | |

| N in γ–iron | 650 | 2.8 | 10.3 |

| 590 | 2.35 | 8.75 | |

| N in α–iron | 590 | 0.10 | 0.40 |

| 20 | < 0.0001 | < 0.0004 | |

Iron and carbon also form an intermediate iron–carbide compound named cementite at equilibrium which has the stoichiometric formula Fe3C. The iron / iron–carbide equilibrium phase diagram, figure 1.2, represents the domains of stable phases as a function of temperature and composition assuming that graphite is suppressed.

All the solid state transformations from austenite to ferrite take place by nucleation and growth, with the parent and product phases coexisting separated by an interface. The formation of equilibrium phases is often preceded by that of a metastable phase which is quicker to form, due to a smaller activation energy for nucleation.

Bhadeshia [18, 19] proposed a classification considering all the transformations that occur in steels, which is consistent with all available experimental data, as summarised by the flow chart, figure 1.3. The different forms of ferrite are classified into those which grow by a displacive and those that grow by reconstructive mechanisms, as proposed by Guy [20]. The austenite decomposition reactions lead to Widmanstätten ferrite (αw), lower bainite (αlb), upper bainite (αub), acicular ferrite (αa) and martensite (α′) occur by a displacive mechanism, characterised by an invariant–plane strain resulting in surface relief and a plate or lath shaped transformation product. Reconstructive transformations include allotriomorphic ferrite (α), idiomorphic ferrite (αi), and pearlite (P). Since all the elements must diffuse during reconstructive transformation in order to achieve the structural change, these reconstructive transformations are not associated with shear strains. In the eutectoid decomposition reaction which leads to a pearlitic microstructure, ferrite and carbide phases grow ‘cooperatively’ with a common transformation front with the austenite.

Table 1.2 lists the key characteristics of phase transformations in steels after Bhadeshia [18, 21]. Consistency of a characteristic with the transformation concerned is indicated by √, inconsistency by ×, cases where the characteristic is sometimes consistent with the transformation are indicated by ⊗. Many of the characteristics presented in the table are discussed in the next section in the context of the bainite transformation.

The ability of the elements to re–arrange themselves into the a new structure plays an important role in both the nucleation and growth of the product phase. As can be seen in table 1.2, many of the transformation products necessitate diffusion and hence the critical role of temperature in determining structure.

Characteristic | α’ | αlb | αub | αa | αw | α | αi | P |

Nucleation and growth reaction | √ | √ | √ | √ | √ | √ | √ | √ |

Plate Shaped | √ | √ | √ | √ | √ | × | × | × |

IPS shape change with large shear | √ | √ | √ | √ | √ | × | × | × |

Diffusionless nucleation | √ | × | × | × | × | × | × | × |

Only carbon diffuses during nucleation | × | √ | √ | √ | √ | × | × | × |

Reconstructive diffusion during nucleation | × | × | × | × | × | √ | √ | √ |

Often nucleates intragranularly on defects | √ | × | × | √ | × | × | √ | × |

Diffusionless growth | √ | √ | √ | √ | × | × | × | × |

Reconstructive diffusion during growth | × | × | × | × | × | √ | √ | √ |

Atomic correspondence during growth; |

|

|

|

|

|

|

|

|

- shared by all atoms | √ | √ | √ | √ | × | × | × | × |

- for atoms in substitutional sites | √ | √ | √ | √ | √ | × | × | × |

During growth; |

|

|

|

|

|

|

|

|

- bulk redistribution of substitutional atoms | × | × | × | × | × | ⊗ | ⊗ | ⊗ |

- local equilibrium at interface | × | × | × | × | × | ⊗ | ⊗ | ⊗ |

- local paraequilibrium at interface | × | × | × | × | √ | ⊗ | ⊗ | × |

Diffusion of carbon during transformation | × | × | × | × | √ | √ | √ | √ |

Carbon diffusion-controlled growth | × | × | × | × | √ | ⊗ | ⊗ | ⊗ |

Co-operative growth of with cementite | × | × | × | × | × | × | × | √ |

High dislocation density | √ | √ | √ | √ | ⊗ | × | × | × |

Incomplete reaction phenomenon | × | √ | √ | √ | × | × | × | × |

Necessarily has a glissile interface | √ | √ | √ | √ | √ | × | × | × |

Orientation relationship within Bain region | √ | √ | √ | √ | √ | × | × | × |

Grows across austenite grain boundaries | × | × | × | × | × | √ | √ | √ |

High interface velocity at low temperatures | √ | √ | √ | √ | √ | × | × | × |

Displacive transformation mechanism | √ | √ | √ | √ | √ | × | × | × |

Reconstructive transformation mechanism | × | × | × | × | × | √ | √ | √ |

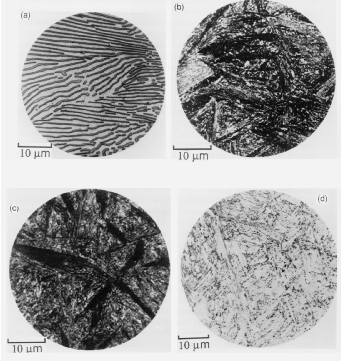

The bainitic microstructure was first identified as a result of systematic isothermal transformation experiments by Davenport and Bain [22], who reported the discovery of an ‘acicular, dark etching aggregate’ formed after isothermal holding between the temperatures for pearlite and martensite formation. The microstructures (reproduced in figure 1.4) were unlike martensite or pearlite observed in the same steel, and were found to be represented by their own ‘C–curve’ on the time–temperature–transformation (TTT) diagrams which they introduced as a convenient way to represent the time dependence of transformation at different temperatures. They suggested that the new microstructure ‘forms much in the manner of martensite but is subsequently more and less tempered and succeeds in precipitating carbon’. Figure 1.5 shows an example TTT diagram reported by Davenport and Bain for a high carbon alloy.

Describing the bainitic structure Hultgren also proposed that ‘needles of troostite’ (later named bainite) first formed as martensite needles which were then self–tempered [24] being able to reject carbon and form carbides due to the higher temperature of transformation than that associated with martensite.

An acicular or plate shape is often the result of a displacive transformation, as will be discussed later in this chapter. An explanation was therefore sought to explain the sluggish transformation of bainite in comparison to martensite. The martensite transformation is usually so rapid that it can often be regarded as only being dependent on temperature. At the time many wrongly supposed that martensite springs fully formed from the matrix rather than by a nucleation and growth mechanism [25]. It was argued that the slower growth meant that bainite must not be a martensitic transformation. Robertson made a study of the transformation rate of the microstructures formed upon quenching from austenite and proposed that the slow growth of the ferritic constituent of bainite is best explained by transformation being controlled by carbon diffusion [26]. Other work emphasised the similarity to martensite, and it was understood that bainite formed with a supersaturation of carbon [27, 28, 29, 30]. Vilella [31] and Bain [32] proposed that transformation involved the formation of flat plates which form abruptly, before decarburising at a rate depending on the temperature. The process to reject carbon from the ‘quasi–martensite’ was proposed to take millionths of a second.

It was recognised that the form of bainite was different in different temperature ranges as can be seen in figure 1.4. Mehl introduced the two main classifications of upper bainite and lower bainite [33], with lower bainite transforming at lower temperatures than upper bainite. Upper bainite has also been referred to as feathery bainite [25]. Intermediate forms were also recognised to exist as a result of continuous cooling transformations. Figures 1.4(b) and (c) show upper and lower bainite respectively. In the optical microscope lower bainite can be described as being similar in appearance to tempered high carbon martensites, while upper bainite more closely resembles low carbon martensite [34]. Observation by transmission electron microscopy later clearly demonstrated that the different types are due to the nature of carbide precipitation, and can be influenced by changing carbon content and temperature. In upper bainite, carbides precipitate from austenite between the plates which have become enriched in carbon, with the upper bainitic ferrite remaining free from carbides. In lower bainite there is also a finer dispersion of plate–like carbides inside the ferrite plates. Carbides have been observed to precipitate in a single crystallographic variant within a given ferrite plate, whereas in martensite tempering generally leads to precipitation of many variants [21].

In steels where transformation to pearlite could be delayed, it could be observed that the maximum degree of transformation to bainite decreased with increasing temperature [35, 36] and there was a critical temperature above which bainite would no longer form. The transformation to bainite below this temperature would often stop, to be followed by pearlite [36]. Dilatometric experiments on a range or steels of different carbon contents, showed that the total expansion increased with greater under–cooling. Higher carbon contents allowed transformation at lower temperatures, resulting in a greater expansion upon transformation [37]. In each case the bainite transformation would cease before all of the austenite was consumed, even though the steels were able to continue to transform to pearlite when heated to a higher temperature.

X–ray diffraction indicated that the austenite remaining in steels exhibiting this incomplete reaction phenomenon was higher in carbon. Klier and Lyman took this to imply that the austenite decomposed before the bainite transformation, into carbon depleted and carbon enriched zones [36]. A similar suggestion had also been made by Kurdjumov regarding transformation to Widmanstätten ferrite [38]. The idea was taken up later by Entin [39] but Aaronson et al. showed that austenite could not perform this spontaneous spinodal decomposition, although this does not rule out random fluctuations of composition which may play a role in nucleation [40, 41].

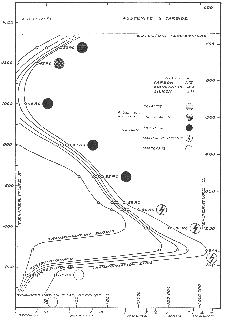

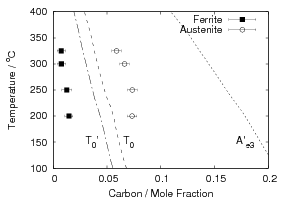

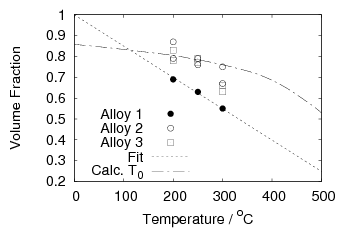

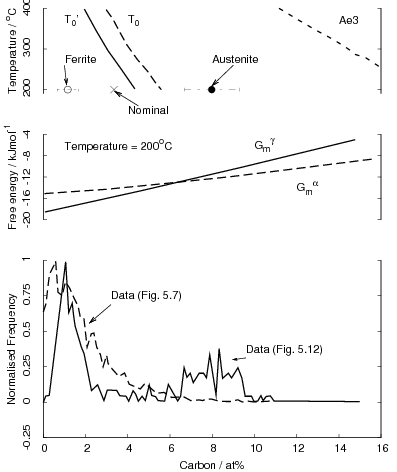

Zener introduced a thermodynamic description of the phase transformations in steels [42, 13]. For bainite he assumed that bainite growth is diffusionless, with any subsequent supersaturation of carbon in the ferrite partitioning into the residual austenite after growth. In comparison to martensite the bainite would grow without introducing a strain into the microstructure and therefore not requiring extra energy as a driving force. Bainite would therefore grow below the temperature where austenite and ferrite of the same composition have the same free energy (T0, see figure 1.6). This explained the critical temperature for bainite formation, but Zener explained the incomplete transformation as due to carbide precipitation ahead of the bainite growth front. Later Wever and Lange extrapolated the ferrite/ ferrite + austenite phase boundary to lower temperatures which explained the ‘incomplete reaction’ [43]. During isothermal transformation the austenite is enriched with carbon, and can no longer continue when the locus of the T0 curve is reached.

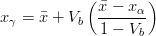

In the absence of carbide precipitation then the volume fraction of bainite V b is given by:

| (1.1) |

where is the average carbon content of the alloy, xγ is the carbon content of the austenite, and xα is the final carbon content of the ferrite, which can often be assumed to be negligibly small.

A plate (or sub–unit) of bainite forms with supersaturation of carbon which is then rejected into the residual austenite. The next plate of bainite then has to grow from the carbon enriched austenite. This process must cease when the austenite carbon concentration reaches the T0 curve, since nucleation of the next ferrite plate is thermodynamically unfavourable. If the reaction occurred with diffusion, the ferrite should continue to grow until the carbon para–equilibrium carbon concentration and the transformation would then go on until the carbon concentration of austenite reached the Ae3 curve.

The consequences of the T0 curve are that greater volume fractions of bainite can be achieved by transformation at lower temperatures, and that equilibrium carbon concentration of austenite given by the Ae3 curve cannot be reached, as is observed experimentally. The remaining austenite is available for further transformations, or can be retained after the sample is cooled to room temperature. The austenite can also be present both in the form of large volumes were little bainite has formed ‘blocky austenite’ and as thin films between the bainitic ferrite plates. The final form of the retained austenite is important for the mechanical properties of the steel, both the morphology and the composition, which effects the susceptibility and the consequences of further transformation to martensite during deformation.

Le Houillier et al. studied steels in which cementite precipitation was prevented, they suggested that a strain energy term should be included in the critical Gibbs energy for the bainite transformation [44]. Bhadeshia and Edmonds estimated the effect of strain and interfacial energy as 270 J mol−1 and denoted the calculated line T0′ [45, 46]. Later Bhadeshia took data from Steven and Haynes [47] and calculated the Gibbs energy for the ferrite and austenite at the BS temperature, and found that the value for the strain energy should be 400 J mol−1 [48].

The diffusion rate of carbon in steel is many orders of magnitude greater than that for substitutional elements, meaning true equilibrium is unlikely to be reached at a transformation interface, especially as the temperature is reduced. The concept of paraequilibrium calculation was introduced, defined as a constrained equilibrium with carbon being able to diffuse freely but without change of any of the solute elements [49]. This is reasonable in many cases, because the diffusivity of carbon can be many orders of magnitude faster than solute diffusion or self–diffusion of iron. The bulk substitutional element content of bainitic ferrite has been shown to be identical to the parent austenite in atom probe experiments by Bhadeshia and Waugh [50, 51], Stark et al. [52, 53] and Josefsson and Andren [54] consistent with a displacive transformation mechanism.

Irvine and Pickering [56], and Shackleton and Kelly [57] observed bainite crystallography using electron diffraction, the crystallographic relationship between the ferrite and carbide components of bainite strengthened the concept that carbides in upper bainite precipitates from carbon enriched austenite, whereas carbides in lower bainite precipitate form from supersaturated ferrite plates (figure 1.7). Pickering [58] showed that both upper and lower bainite can occur during isothermal transformation at the transition temperature.

Matas and Hehemann [59] proposed that the transition from upper to lower bainite was decided by the time taken for carbon to partition compared to the time taken to precipitate carbides within the ferrite. Upper bainite forms at higher temperatures where carbon can partition to the austenite before it can precipitate in the ferrite. Takahashi and Bhadeshia [55] produced a quantitative model for the transformation comparing the time required to decarburise a super–saturated plate against cementite precipitation kinetics.

As we would expect lower bainite is more likely to form in high carbon alloys, and upper bainite more likely in lower carbon alloys. Not only is there more carbon to precipitate, but higher carbon contents mean that transformation is delayed to lower temperatures in continuously cooled samples. Srinvasan and Wayman [60] found that lower bainite formed at the bainite start temperature (BS) in a Fe-1.1C-7.9Cr wt% alloy and Ohmori and Honeycombe [61] showed that in high purity Fe–C alloys lower bainite is not obtained when carbon concentration is less than around 0.4 wt%.

Ko and Cottrell [62] studied the bainite transformation in situ using hot stage microscopy and reported surface relief similar to martensite. Growing plates also stopped when they reached austenite grain boundaries, which is not necessary for reconstructive transformations. Surface relief is consistent with a displacive transformation mechanism, while the observed slow growth rates support the idea that transformation is controlled by diffusion.

Oblak and Hehemann [34] rationalised the seemingly contradictory observations after studying the microstructures formed using electron microscopy, and observing that the microstructural unit was smaller than previously accepted. The apparent slow growth rates at the macroscopic scale could now be attributed to the growth of bainite by the repeated nucleation of ‘sub–units’, each of which grows rapidly to a limited size. The features which were thought to be plates were actually ‘sheaves’ [63] or ‘packets’, aggregate structures made up of these smaller sub–units or platelets. Figure 1.8 is the schematic representation of structures observed. The ‘macroscopic’ growth rate of the sheaf is therefore slower than the martensite transformation because it is largely controlled by the nucleation rate of these sub–units, although they transform by a martensitic mechanism, each one forming an acicular parallel plates around 0.2-0.5 μm in width and 1-10 μm in length.

Greninger and Troiano measured the crystallographic orientation of austenite and showed that the habit planes of bainite and martensite are both irrational, and that the habit plane of bainite is different from that of martensite in the same steel [64]. The habit planes varied with carbon content and transformation temperature. Observing that the habit plane of bainite approached that of Widmanstätten ferrite at high temperatures and that of proeutectoid cementite at low, Greninger and Troiano proposed that bainite grew from the beginning as an aggregate of ferrite and cementite, with competition between the two controlling the habit plane.

Smith and Mehl [25] later showed that the orientation relationship between bainitic ferrite and austenite does not vary greatly with varying carbon content or transformation temperature, and that it is similar to that for martensite and Widmanstätten ferrite, but dissimilar to pearlitic ferrite/austenite. Using pole figure analysis they determined that bainite had a Nishiyama–Wasserman [65, 66] relationship at 450 and 350∘C but bainite transformed at 250∘C and martensite had a Kurdjumov-Sachs [67] orientation relationship. Pickering showed that adjacent platelets in a cluster have almost identical crystallographic orientation [58], and are often found to be touching, separated by low–angle boundaries. Observing that this could lower the stored energy in the microstructure, and help to stabilise the structure against tempering. Davenport also reported the relationship could be loosely described as the Kurdjumov-Sachs type [68]. Crosky et al. [69] showed the orientation relation between the BCC and FCC phases after transformation are always found to be close to but never exactly the Kurdjumov–Sachs or Nishiyama–Wasserman orientation.

Kurdjumov–Sachs orientation relationship

{111}γ||{011}α

γ||

γ|| α

α

Nishiyama–Wasserman orientation relationship

{111}γ||{011}α

γ ≈ 5.25∘ from

γ ≈ 5.25∘ from  α towards

α towards  α

α

Greninger–Troiano orientation relationship

{111}γ ≈ 0.2∘ from {011}

α

γ ≈ 2.7∘ from

γ ≈ 2.7∘ from  α towards

α towards  α

α

The relative orientations of the bainitic ferrite to the parent austenite have since frequently been found to be consistent with it being the Kurdjumov–Sachs or Nishiyama–Wasserman relationships, although neither is ever exactly matched. The two relationships differ by a rotation of about 5.25∘ about the normal to the parallel close–packed planes of the two structures. In martensite the relative orientation is found to be intermediate and irrational as predicted by crystallographic theory [19].

A high accuracy is required to compare theory with experiment, in bainite and martensite the required accuracy is difficult to achieve because of the experimental difficulties of retaining austenite and also the high dislocation densities. However experimental data always lie within the ‘Bain region’ which encompasses the Kurdjumov–Sachs and Nishiyama–Wasserman relationships [19]. The Bain region is defined as a result of the lattice deformation, which can be factorised into two components; the Bain strain which is the pure part of the lattice deformation, and a rotation of not more than 11∘ [19]. During the Bain strain no plane or direction is rotated by more than 11∘ since the two possible rational relations differ by a relative rotation of 5.25∘ about the normal to the parallel close–packed planes. This need not be the case for reconstructive transformations. For example allotriomorphic ferrite is known to grow into austenite grains with which it has an orientation which is random, or outside the Bain region, while during austenite grain boundary nucleation grows in orientation that is close to Kurdjumov–Sachs or the Nishiyama–Wasserman relationship [19].

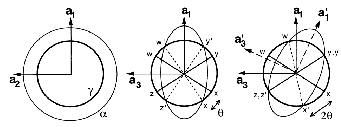

The face–centred cubic structure of austenite can also be described by a body–centred tetragonal unit cell, which can be converted to the body–centred tetragonal structure of martensite or to a body–centred cubic structure by contraction and expansion of the cell parameters. These deformations were first proposed by Bain and are known as the Bain strain [70]. Figure 1.9 shows the equivalence between the body–centred tetragonal (BCT) and face–centred cubic structures.

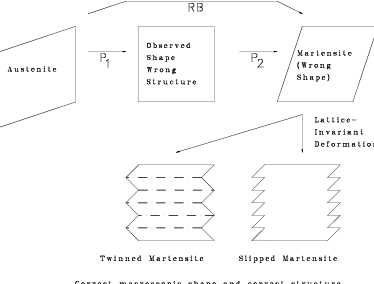

Although the Bain strain would produce the necessary change in crystal structure the macroscopic shape change would not be the same as the observed shape change, there is a further condition for a displacive transformation, that is the movement of a glissile interface through the parent phase. Wechshler et al. [71] and Bowles and Mackenzie [72, 73] developed a crystallographic theory to explain the transformation based on the movement of a glissile interface between the parent and product phases, and is consistent with the observed shape change.

A pure deformation can be combined with a rigid body rotation to give a net lattice deformation which leaves a single–line undistorted, figure 1.10. However it is not possible to make a rotation that leaves two non–parallel lines undistorted so it is not possible to have an invariant–plane strain. This means it is impossible to have an interface between austenite and ferrite which is fully coherent and stress free, or transform between the phases with a strain that is an invariant–plane strain. To compensate for this discrepancy it is necessary to introduce a lattice–invariant deformation such as twinning of slipping as shown in figure 1.11. Such a substructure of twins or of slip steps is observed experimentally in martensite.

Displacive or martensitic transformations (e.g. transformation to martensite and bainite) conform to the phenomenological theory of martensite crystallography [72, 73]. Each of the requirements follows as a consequence of an invariant–plane strain deformation or the absence of substitutional atom diffusion.

Points 3, 4, 5 do not apply to face–centred cubic → hexagonal close–packed transformations.

The similarity between the bainitic and martensitic transformations is long established [22] and received added emphasis when is was shown that both transformations exhibit surface relief [62].

Hull [74] and later Bilby and Christian [75] proposed that martensitic transformations can be distinguished experimentally by means of the change in shape of the transformed regions. Christian also commented that surface relief does not necessarily result from non–diffusional transformation [76], and can also result in cases were the solute atoms can diffuse orders of magnitude faster than the solvent. Therefore surface relief cannot tell us if a displacive transformation takes place with or without carbon diffusion, however it is a necessary feature of martensitic transformation because of the lattice correspondence between the parent and product phases. Martensite, bainite, and Widmanstätten ferrite all exhibit a surface relief, with martensite transformation taking place with no carbon diffusion and the Widmanstätten transformation being controlled by carbon diffusion.

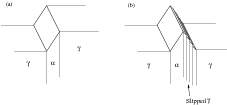

Surface relief when characterised as an invariant–plane strain with a large shear component can be taken to signify that the transformation mechanism involves the cooperative transfer of atoms from the parent to the product phase in a manner characteristic of shear transformations. The surface relief should be invariant–plane strain as in martensite, and has been characterised as having a shear strain component of 0.22 and a volume strain of 0.03 on transformation [77].

During transformation, one crystal grows at the expense of another by the migration of the interface. Christian [76] has said that a shape change in the transforming region can be expected for an appropriately coherent boundary between the parent and product phases of the martensitic type, provided the correspondence is not destroyed by diffusion. Assuming the crystals on each side of the boundary remain in contact, and remain coherent as the boundary moves, then any macroscopic shape change must be an invariant–plane strain on the plane at the boundary, or must differ from it only by strains that can be accommodated elastically in the vicinity of the boundary.

The strain energy for bainite when the shape change is elastically accommodated has been calculated to be about 400 J mol−1 [21], although there is the possibility that some of the strain can be relaxed by plastic deformation. One consequence of plastic deformation during or after transformation is the plastic yielding of austenite at the surface. Figure 1.12 shows the typical effects of the invariant–plane strain. The strain is followed or accompanied by a plastic relaxation in the austenite, resulting in a distinctive shape.

The transformation strain is a combination of the Bain strain and a rigid body rotation; it is an invariant–line strain. A further inhomogeneous lattice–invariant deformation, by shear or twinning, makes the transformation strain macroscopically an invariant–plane strain. The invariant–plane is also known as the habit plane. Figure 1.13 shows the nature of the invariant–plane strain, while experimental results are summarised in table 1.3 for different microstructures.

Swallow and Bhadeshia measured the surface topography using atomic force microscopy [77] and concluded that the relief of each sub–unit conformed with the general features of an invariant–plane strain. Whereas the nature of the shape deformation of Widmanstätten ferrite and martensite can be observed in the optical microscope, the bainite sub–units cannot because they are on a much finer scale. Atomic force microscopy is capable of resolving the bainite sub–units, the value of the shear component measured using light microscopy is around 0.13 [60, 78]. Theoretical predictions of the shear lie in the range 0.22-0.28 [77]. Measurement of the displacement of twin boundaries following transformation observed in the transmission electron microscope gives a value of 0.22 [79].

| Transformation | s | δ | Morphology | Reference |

| Widmanstätten ferrite | 0.36 | 0.03 | Thin Plates | Watson and McDougall [80] |

| Bainite | 0.22 | 0.03 | Thin Plates | Sandvik [81] |

| Bainite | 0.26 | Thin Plates | Swallow and Bhadeshia [77] | |

| Martensite | 0.24 | 0.03 | Thin Plates | Dunne and Wayman [82] |

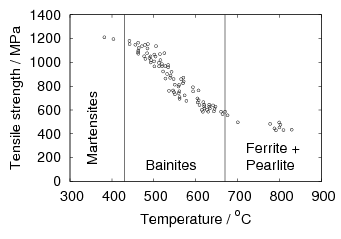

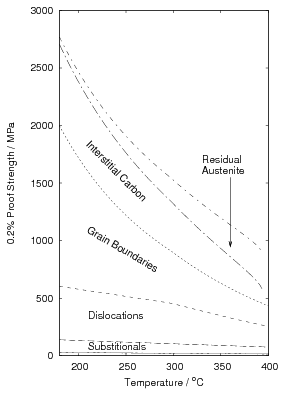

In general the strength of steels can be increased by lowering the temperature of the austenite to ferrite transformation [58], as shown in figure 1.14 lowering the transformation temperature usually increases the intensity of all the strengthening mechanisms. It is generally true that lower temperature results in finer grain size of the transformation product, greater dislocation density, finer dispersion of precipitated phases, and greater retention of solute in supersaturated solution. The results of Pickering [58] show a linear relationship between the transformation temperature and the strength over a wide range of bainite transformation temperatures, Davenport and Bain reported similar results for hardness after isothermal transformation [22]. It is also observed that upon continuous cooling fully martensitic steels can generate higher strengths than bainitic steels, usually tempering is performed on these martensitic steels to reduce the strength so as to provide adequate toughness prior to use.

Early bainitic steels were found to not be generally better in terms of mechanical properties than quenched and tempered martensitic steels due to the large size of the carbides, and the extra difficulty in implementing isothermal transformation. Irvine and Pickering introduced low carbon steels alloyed with boron and molybdenum [83] which delayed the pearlite transformation but maintained sufficiently fast bainite transformation kinetics, to allow production of fully bainitic steels by continuous cooling heat treatment. Later, higher cooling rates were introduced by using a laminar water jet system [84], and leaner alloys could be produced with higher strengths, leading to the development of High–Strength–Low–Alloy steels [85]. Relative to martensitic steels, the bainite microstructure is more stable upon further heat treatments, and bainitic steels have also been developed as creep resistant steels, for example composition Fe-0.1C-2.25Cr-1Mo wt% which exhibits excellent creep strength and microstructural stability [86]. Although the details of the microstructure may not have been known at the time it is now known to be a carbide–free upper bainite [19].

It is also known that addition of silicon or aluminium can prevent cementite precipitation during the bainite transformation. This is due to the high penalty of having silicon present in the cementite structure. In high silicon steels large carbides, which can lower the toughness of steel are prevented and the bainite plates are separated by thin films of retained austenite as have been studied by Bhadeshia and Edmonds [45].

Important classes of steels have been developed to take advantage of retained austenite to provide extra sources of plasticity. Transformation induced plasticity (TRIP) and TRIP–assisted steels [87, 88, 89], multi–phase steels (so called dual–phase steels), and more recently still, twinning induced plasticity (TWIP) aided steels [90, 91]. TRIP was first observed in heavily alloyed austenitic stainless steels, during deformation above their martensite start temperature. Matsumura reported the potential of TRIP–aided carbide–free steels, where carbon enrichment in the austenite resulting from transformation was used to stabilise the austenite. This greatly reduced the price of the stabilisation, and the effect could then be used to enhance the ductility of cold–formed high strength steels for automotive applications. In dual phase steels, inter–critical annealing replaces full austenitisation, in this case transformation to bainite takes place from a mixture of ferrite and austenite. For the same composition this may result in a greater amount of retained austenite, present in more refined regions.

The bainite transformation has been utilised to achieve areas of austenite of sufficient enrichment of carbon that they are stable enough to be retained in the microstructure, but are available for transformation upon deformation. In these TRIP–assisted steels the presence of retained austenite allows the strain–hardening rate to be decreased, or maintained to higher elongation. The ability of bainitic steels to produce retained austenite in the final microstructure has allowed a greater manipulation of the resultant mechanical properties.

This thesis describes the characterisation of a remarkable new bainitic steel, which

exhibits very high strength and hardness in bulk samples. The bainitic structure

which forms at low temperature in these high–silicon high–carbon steels offers

unique combination of mechanical properties, with strength of up to 2.5 GPa and

a toughness up to 28 MPa , depending on transformation temperature,

reported by Garcia-Mateo et al. [2].

, depending on transformation temperature,

reported by Garcia-Mateo et al. [2].

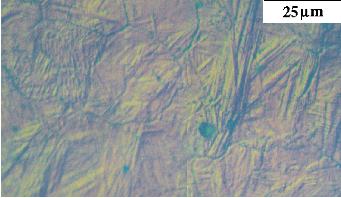

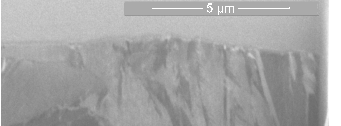

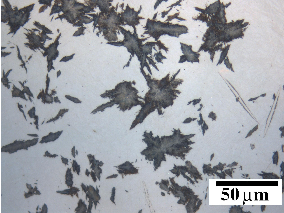

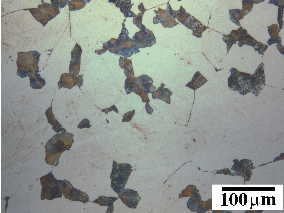

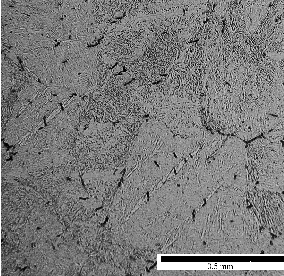

These mechanical properties are a result of a highly refined bainitic microstructure as shown in figure 1.15, due to transformation from austenite at temperatures of around 200∘C. Embrittling carbides are negated by the silicon additions. The microstructure then consists simply of plates of bainitic ferrite separated by thin films of austenite, the scale of both being unusually fine. Ferrite plates are reported to have widths of 20 nm compared to the usual width of 0.2 to 0.5 μm. Large regions of ‘blocky’ retained austenite which would otherwise limit the toughness could be avoided by maximising the volume fraction of ferrite, by transformation at the reduced temperature.

On a coarser scale the microstructure resembles wedge shaped sheaves of bainite (clusters of fine bainite plates separated by thin films of austenite when viewed at higher resolution) and small blocks of residual austenite, as shown in figure 1.16.

Transformation at low temperature not only results in high volume fraction of ferrite, but also leads to high strength by introducing a high number of defects into the microstructure. The defects take the form of dislocations and grain boundaries. The high dislocation density in the bainitic ferrite results in a huge supersaturation of carbon in the ferrite after transformation. It therefore seems remarkable that the hardness is also observed to be resistant to harsh heat treatments.

Caballero et al. [3] were the first to report transformation of high–carbon high–silicon steels at low–temperatures could result in nanoscale microstructure and result in extremely high strength steels. The discovery resulted from the investigation into the design of mixed microstructures of bainite and martensite to be produced from continuous cooling in medium carbon steels (e.g. Fe-0.3C-1.51Si-1.42Cr-0.25Mo-3.53Ni, Fe-0.32C-1.45Si-1.97Mn-1.26Cr-0.26Mo-0.1V) [94, 95]. Those steels have predominantly a bainitic microstructure consisting of fine plates of upper bainitic ferrite separated by thin films of stable retained austenite. Thermodynamics were utilised to design alloys so as to maximise the volume fraction transforming to the fine bainite structure, to avoid the large areas of retained austenite detrimental to toughness, by shifting the T0 curve to higher carbon contents, and by minimising the average carbon content [94].

Toughness values of nearly 130 MPa were obtained along with

strength in the range 1600-1700 MPa; these values match the critical

properties of marageing steels which are at least 30 times more expensive

to manufacture due to high alloy content of cobalt and nickel [95]. The

properties are also superior to quenched and tempered martensitic steels,

dual phase steels and TRIP-assisted steels as shown in figure 1.17. The

microstructure is resistant to tempering up to the transformation temperature,

however tempering at higher temperatures lead to the decomposition

of the austenite into ferrite and carbides, lowering both strength and

toughness.

were obtained along with

strength in the range 1600-1700 MPa; these values match the critical

properties of marageing steels which are at least 30 times more expensive

to manufacture due to high alloy content of cobalt and nickel [95]. The

properties are also superior to quenched and tempered martensitic steels,

dual phase steels and TRIP-assisted steels as shown in figure 1.17. The

microstructure is resistant to tempering up to the transformation temperature,

however tempering at higher temperatures lead to the decomposition

of the austenite into ferrite and carbides, lowering both strength and

toughness.

Microprobe analysis was used to determine the composition of the retained austenite and to investigate the properties of the austenite a steel was produced with the same composition: Fe-0.80C-1.60Si-1.99Mn-1.29Cr-0.25Mo-0.1V [98] (alloy A in this thesis). Although present as retained austenite within the bainitic microstructure, the composition was found not to produce a stable fully austenitic structure when in the bulk form [3, 98], with transformation to martensite taking place at around 120∘C. Subsequent experiments revealed that the steel could be transformed isothermally to bainite at temperatures as low as 125∘C.

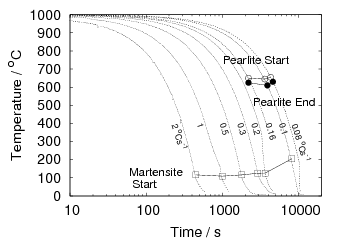

Isothermal transformation experiments were conducted at 125, 150, 190, 250 and 300∘C, using hardness and optical microscopy to follow the progress of transformation and also using X–ray diffraction to quantify the volume fractions transformed. Bainitic microstructures with hardness around 600 HV could be produced by transforming at temperatures of 190 and 250∘C. These microstructures consist of around 60-70% of bainitic ferrite, with a plate size of around 50 nm separated by films of retained austenite which were even thinner [3]. The bainite transformation had a separate C–Curve on the TTT diagram with a well defined bainite start temperature as shown in figure 1.18.

Transformation to predominantly bainitic microstructures at similar temperatures has previously been reported by Davenport and Bain as early as 1930 [22], to temperatures as low as 140∘C as we saw figure 1.5. Although not reported it is probable that these microstructures contained large cementite particles due to the lower silicon content compared to the steels of Caballero et al.. However it may be noteworthy that Davenport and Bain did observe that austenite could be retained in the microstructures after transformation at low temperatures (140∘C) in some steels when the microstructure was bainite (referred to as martensite–trootsite in their paper) but only trace amounts were observed after transformation to martensite. Transformation at 180∘C resulted in a hardness of 62 Rockwell C (≈745 HV 2 ) and 64 Rockwell C (≈800 HV) at 140∘C along with 20-25 % retained austenite in Fe-1.13C-0.30Mn-0.17Si wt% alloy. An Fe-0.78C-0.36Mn-0.16Si wt% alloy achieved a hardness of 56.5 Rockwell C (625 HV) at a transformation temperature of 180∘C, this steel was the only one in the study which retained austenite after transformation at 180∘C.

All of the alloys studied by Davenport and Bain also had relatively fast transformation kinetics for diffusional products at higher temperatures, many of the transformation curves touching the axis at higher temperatures. Despite the fast cooling rates achievable by quenching into tin. It is possible that their hypereutectic steels would form cementite along the grain boundaries, which could have a devastating effect on toughness and the elongation in tensile tests. It is not known if Davenport and Bain pursued any further transformation experiments at low temperatures, since their main aim in this work seemed to be the classification of microstructures, and their work turned up many fruitful avenues of research.

Sandvik has previously studied the isothermal transformation in high–carbon high–silicon steels to bainite at 380∘C [100]. The steels of composition Fe-0.99C-2.21Si-0.78Cr-0.48Mn-0.017P-0.016S-0.035Al and Fe-0.91C-2Si-0.42Cr-0.59Mn-0.017P-0.031S-0.032Al wt% reporting that the steels exhibited a two stage transformation. Initially transformation rates were fast, followed by slow decomposition by formation of triclinic carbide and decomposition of the remaining austenite to ferrite. Sandvik attributed the delayed reaction of the second transformation as to it being governed by diffusion of carbon. The triclinic carbide is related closely to cementite, and due to the crystallographic relationships, crossings between carbide plates, and faulting on the (010)C planes it is thought the carbide forms by a shear mechanism.

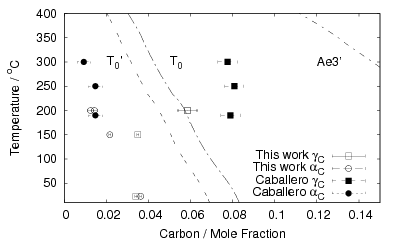

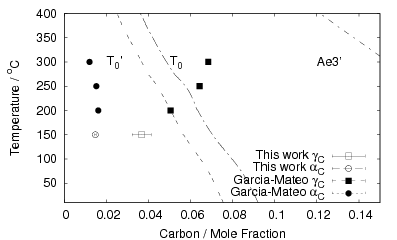

Garcia-Mateo et al. transformed steel of composition Fe-0.98C-1.89Mn-0.26Mo-1.26Cr-0.09V<0.002P (alloy B) at a range of temperatures and used X–ray diffraction to measure the carbon content of austenite and ferrite from the lattice parameter as shown in figure 1.19. The values indicated that there is high supersaturation of carbon in the ferrite and the level of carbon in the austenite determined in this way is higher than expected from calculation of T0’. One exception to the expected trend is that the level of enrichment of carbon in austenite is no higher than when transformed at 200 than 250∘C.

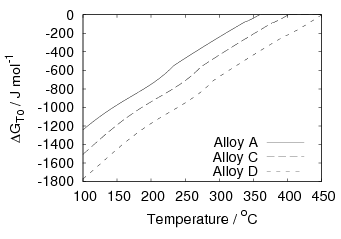

Garcia-Mateo et al. [102] then performed a series of thermodynamic calculations to see the effect of varying composition upon transformation kinetics, for the design of further alloys. A series of alloys were also produced to investigate the effect of various alloying elements. Comparison of the transformation kinetics against those calculated considering thermodynamics, as shown in figure 1.18 is very useful for design of further alloys. Garcia-Mateo calculated the effect of the different alloying elements, table 1.4 using thermodynamic calculation after Bhadeshia [48] and proposed further alloys with ferrite stabilising elements cobalt and aluminium to supply extra driving force for the transformation to bainite [103]. The characteristics of these alloys of composition Fe-0.83C-1.57Si-1.98Mn-0.24Mo-1.02Cr-1.54Co (alloy C) and Fe-0.78C-1.49Si-1.95Mn-0.24Mo-0.97Cr-1.6Co-0.99Al (alloy D) were reported in a series of papers [103, 104, 105, 106]. Figure 1.20 shows the difference in the driving force for transformation between the two alloys and alloy A.

| Element | Range in alloys | Effect on

| ||

| produced | T0 | BS | MS |

|

| C | 0.79–0.98 | — | ↓ | ⇓ |

| Si | 1.29–1.67 | ↓ | — | — |

| Mn | 1.5–3.79 | ↓ | ⇓ | ↓ |

| Mo | 0.21–0.25 | ↓ | ↓ | ↓ |

| Cr | 0.92–1.33 | ↓ | ⇓ | ↓ |

| Co | 0–1.5 | ↑ | ↑ | — |

| Cu | 0–0.2 | ↓ | — | — |

| Al | 0–0.2 | ↑ | ↑ | — |

| W | 0–1.0 | ↓ | ⇓ | — |

| V | 0–0.1 | — | — | — |

| Ni | 0–0.005 | ↓ | ↓ | ↓ |

The new alloys achieved faster transformation into the low–temperature bainite microstructure, and similar hardness values were realised [103]. The time to complete transformation at 200∘C was reduced from 310 h in alloy A to 160 h with addition of cobalt in alloy C, and 80 h with addition of both cobalt and aluminium in alloy D. Further acceleration could be achieved by lowering the austenitisation temperature to achieve grain refinement of the austenite, using equilibrium thermodynamic calculations to transform at temperatures were a small amount of carbides were present at the austenitisation temperature.

Garcia-Mateo et al. [107] also investigated the applicability of the nucleation functions as previously applied by Bhadeshia [48, 108] and Ali and Bhadeshia [109] to describe transformation to bainite and Widmanstätten ferrite. The bainite start temperature in the novel low–temperature bainitic steels could be explained by the parameters which had been previously derived at higher temperatures. Bainite forms below the calculated T0’ temperature when; ΔGγ→α < −G SB and ΔGm < ΔGN. GN being a universal nucleation function, describing the nucleation rate of bainite or Widmanstätten ferrite as a function of temperature.

The plate size of the bainitic ferrite and the hardness were measured as a function of transformation temperature in alloys C and D [103]. Figure 1.21 shows the trend of hardness as related to plate size. A higher correlation was observed after calculating the area of interface per unit volume, SV , by accounting for the plate size and the volume fraction of bainite forming. There is some indication that the plate size does not depend upon just the transformation temperature. The alloys were transformed after two different austenitisation temperatures, and the measured plate size was smaller following the austenitisation at the lower temperature, some confidence in these values can be taken in that the samples with smaller plate size have a higher hardness. Austenitisation at the lower temperature will mean that carbides are present during austenitisation, effectively decreasing the concentration of carbon in the bulk.

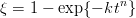

Mechanical properties and structure resulting from isothermal transformation

are summarised in tables 1.5–1.8 [3, 98, 4, 105] for the alloys with compositions

as shown in table 1.9. The tensile strength of the alloys C and D were measured

after isothermal transformation at 200, 250 and 300∘C [4], the stress–strain curves

for alloy C are shown in figure 1.22. In alloy C, transformation at 200∘C gave a

tensile strength of 2.15 GPa, with a yield strength of 1.4 GPa an elongation of 5%

and a fracture toughness (KIC) of 32 MPa . Transformation at higher

temperatures produces lower strength and greater ductility and toughness. In the

same alloy transformed at 300∘C the ultimate tensile strength was 1.8 GPa, yield

strength 1.3 GPa fracture toughness 45 MPa

. Transformation at higher

temperatures produces lower strength and greater ductility and toughness. In the

same alloy transformed at 300∘C the ultimate tensile strength was 1.8 GPa, yield

strength 1.3 GPa fracture toughness 45 MPa and elongation hugely

improved to 29%. The same trend was observed in alloy D, as shown in

table 1.8.

and elongation hugely

improved to 29%. The same trend was observed in alloy D, as shown in

table 1.8.

The carbon content in the bainitic ferrite was measured using X–ray diffraction, as was the dislocation density which was estimated from the peak broadening. It was noted that there was a correlation, and that the carbon enrichment increased with higher dislocation densities.

In alloy A it was observed that the carbon supersaturation in the austenite is no higher after transformation at 200 than at 250∘C. A similar anomaly in the levels of enrichment was also observed in alloys C and D. Rather than the expected trend of increasing austenite carbon content with lower transformation temperature, the opposite trend was observed as the transformation temperature was reduced from 300 to 250 and 200∘C. This was accompanied by lower elongation of the alloys transformed at lower temperatures, which could be related to the lower elongation by decreasing the stability of the austenite.

Garcia-Mateo [110] reported the strain hardening behaviour in the steels transformed at the different temperatures and calculated the austenite content as a function of plastic strain and composition after Sherif et al. [111]. Bhadeshia observed that the results show the amount of austenite at failure is usually around 10%, and related this to the percolation threshold. At around 10% of austenite it is no longer possible to have a continuous matrix and percolation of dislocations is no longer possible resulting in failure [112]. A similar value of the final austenite content for low–temperature bainitic steel has also been observed in the same steels by Sherif [96].

Hase et al. [113] transformed using a two–stage process, stepping the

temperature during transformation, this was able to achieve a higher amount of

retained austenite but avoid large blocks, and achieve a ductility of 40%,

toughness of 63 MPa and UTS of 1.5 GPa. Transforming at 250 and 350

resulted in similar strength level as transformation at 300∘C but better

elongation.

and UTS of 1.5 GPa. Transforming at 250 and 350

resulted in similar strength level as transformation at 300∘C but better

elongation.

| Alloy A | Temperature

| |||

190∘C | 200∘C | 250∘C | 300∘C |

|

| UTS / GPa |

| 2.00 | 1.93 |

|

| YS / GPa |

| 1.68 | 1.53 |

|

| TE |

| 3.1 | 8.8 |

|

KIC / MPa |

|

|

|

|

| Charpy VN / J |

| 4 | 6 |

|

| Hardness / HV20 | 650 | 650 | 575, 590 | 440 |

| Bainitic Ferrite C wt% | 0.32±0.07 |

| 0.32±0.07 | 0.20±0.07 |

| Bainitic Ferrite fraction | 0.87±0.01 |

| 0.84±0.01 | 0.65±0.01 |

| Plate thickness / nm |

|

|

|

|

| Austenite C wt% | 1.72±0.1 |

| 1.76±0.1 | 1.69±0.1 |

| Alloy C | Temperature |

|

||

200∘C | 250∘C | 300∘C | Ref. |

|

| UTS / GPa | 2.15 | 1.95 | 1.8 | [4] |

| YS / GPa | 1.4 | 1.5 | 1.3 | [4] |

| TE / % | 5 | 20 | 29 | [4] |

KIC / MPa | 32 | 38 | 45 | [4] |

| Hardness / HV20 (fine) | 660 | 589 | 500 | [103] |

| Hardness / HV20 | 690 | 640 | 490 | [103] |

| Bainitic Ferrite C wt% | 0.35 | 0.33 | 0.26 | [4] |

| Bainitic Ferrite fraction | 0.83 | 0.79 | 0.63 | [4] |

| Plate thickness / nm | 25 | 42 | 57 | [4] |

| Austenite C wt% | 1.1 | 1.4 | 1.49 | [105] |

| Alloy D | Temperature |

|

||

200∘C | 250∘C | 300∘C | Ref. |

|

| UTS / GPa | 2.2 | 1.9 | 1.7 | [4] |

| YS / GPa | 1.4 | 1.35 | 1.3 | [4] |

| TE / % | 8 | 9 | 29 | [4] |

KIC / MPa | 32 | 35 | 50 | [4] |

| Hardness / HV20 (fine) | 650 | 565 | 500 | [103] |

| Hardness / HV20 | 650 | 640 | 490 | [103] |

| Bainitic Ferrite C wt% | 0.35 | 0.34 | 0.29 | [4] |

| Bainitic Ferrite fraction | 0.87 | 0.79 | 0.74 | [4] |

| Plate thickness / nm | 45 | 42 | 53 | [4] |

| Austenite C wt% | 1.47 | 1.7 | 1.9 | [105] |

Alloy | C | Si | Mn | Ni | Cr | Mo | V | Al | Co | P | S |

A [3] | 0.79 | 1.59 | 1.94 | 0.02 | 1.33 | 0.3 | 0.11 | — | — | — | — |

0.98 | 1.46 | 1.89 | — | 1.26 | 0.26 | 0.09 | — | — | <0.002 | <0.002 |

|

C [4] | 0.80 | 1.59 | 2.01 | — | 1.0 | 0.24 | — | — | 1.51 | 0.002 | 0.002 |

D [4] | 0.78 | 1.49 | 1.95 | — | 0.97 | 0.24 | — | 0.99 | 1.60 | 0.002 | 0.002 |

Due to the high hardness the low–temperature bainitic steels have been investigated for use as armour steels, to replace more expensive armours. Hammond investigated the shock and ballistic properties to provide data for design of armour systems [114]. The strength of the material was found to be better when transformed at the lower temperatures, and can be as high as 10 GPa when the strain rate was 107 s−1 [115]. The armour systems developed from the material were found to be able to defeat the same projectile with a lower mass of armour, when compared against titanium and alumina armour systems [93].

Brown and Baxter criticised the commercial practicality of heat treatments lasting longer than 1 week, and also the cost of adding cobalt to accelerate transformation in these alloys, and claimed to solve these problems by altering the composition although they did not publish the full composition of the alloy they produced [98]. Transformation at 250∘C for 8 h, produced a microstructure with yield stress of 1673 MPa, UTS 2098 MPa and elongation of 8%. They also noted that all of the low–temperature bainitic steels have exhibited low values of Charpy impact toughness when tested at room temperature.

The cost of transforming steel for long periods of time at temperatures around 200∘C should not be expected to be costly in itself. The heat loss from a furnace increases with the operating temperature. For transformation of small samples in the laboratory small ovens are sufficient. For mass production, dedicated facilities are required, since it would always be un–economical to utilise a high temperature furnace which is needed for other applications. Temperature control within a few degrees may be necessary due to sensitivity of the plate size, transformation kinetics and volume transforming, and resulting mechanical properties to temperature.

To achieve very high strengths without introducing additional strengthening mechanisms, it may be unavoidable that long transformation times are needed, if the strengthening is mostly due to the plate size and the plate size is intimately related to the transformation kinetics. As transformation occurs by the repeated nucleation of sub–units, the transformation kinetics are determined by the time between nucleation events, and the volume of the sub–units transforming as a result.

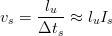

Some models of bainite kinetics assume a constant volume for the sub–unit,

however attempts have also been made to account for the influence of

transformation temperature. There is little data on the volume of the plates, most

attempts have relied on using the plate width data of Chang [116]. Chester and

Bhadeshia modelled transformation kinetics of bainite transformation kinetics,

and showed that a better match could be achieved by considering the size of the

sub–unit. They used a linear relation, UW = 0.001077T − 0.2681, for the plate

width, and length of 10 μm, with a minimum plate width of 0.05 μm [117]. Parker

modelled the plate thickness using the equation 0.2 × (T − 528)∕150 μm. Matsuda

and Bhadeshia used this relation, with all the plate dimensions varying in the

same way, so the volume of the sub–unit varied as; V U = 2 × 10−17 × 3

m3 [118]. Matsuda and Bhadeshia assumed that in the initial stages of

transformation the volume of bainite is controlled purely by nucleation events at

the austenite grain surfaces, neglecting auto–catalysis, the volume of bainitic

ferrite is related to the grain boundary nucleation rate Ig, the volume of the

sub–unit V U, SV the austenite grain boundary surface area per unit volume,

and time t since the start of transformation. After an initial stage they

then considered the lengthening rate of the sheaves of bainite vs to be

dominated by the time interval Δts between nucleation events after Ali and

Bhadeshia [119, 120].

3

m3 [118]. Matsuda and Bhadeshia assumed that in the initial stages of

transformation the volume of bainite is controlled purely by nucleation events at

the austenite grain surfaces, neglecting auto–catalysis, the volume of bainitic

ferrite is related to the grain boundary nucleation rate Ig, the volume of the

sub–unit V U, SV the austenite grain boundary surface area per unit volume,

and time t since the start of transformation. After an initial stage they

then considered the lengthening rate of the sheaves of bainite vs to be

dominated by the time interval Δts between nucleation events after Ali and

Bhadeshia [119, 120].

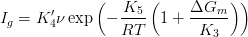

| (1.2) |

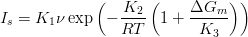

Both of the nucleation rates for the sheave Is and grain boundary Ig are described by equations of the same form;

| (1.3) |

| (1.4) |

where Kn are constants previously derived [121, 122] or derived by Matsuda and Bhadeshia.

These equations treat the size of the sub–unit and the nucleation rate independently, but without a physical model to explain the limit to the plate size this cannot be confirmed. However it is clear to see that independently altering the plate size will proportionally decrease the transformation rate. In the equations presented, during the growth of the sheaves of bainite the growth rate depends only on the length of the bainite sheaf. Therefore long slender plates will be capable of growing quickly but still introducing a large area of interface per unit volume. As can also be seen, the nucleation rate can be increased via the driving force ΔGm which includes temperature and chemical effects.

If the effect is mainly due to the transformation temperature, it may be possible to achieve the same very fine plate size using more quickly transforming alloys, but of course there is a requirement to suppress the martensite start temperature sufficiently.

It would be beneficial to have a lower carbon variant, since high carbon steels are more difficult to weld. Bhadeshia demonstrated with calculations the difficulty of transforming at 200∘C in low carbon steels [123], this is because carbon is the most effective element at widening the gap between the martensite and bainite start temperatures (MS and BS). Alloying with nickel to suppress MS in a 0.1 wt% carbon 2 wt% manganese alloy depresses the BS temperature until it is lower than MS after around 5 wt% of nickel. Yang and Bhadeshia have made an experimental investigation of the possibility of low–carbon super–bainite, in a series of 0.1 wt% carbon steels, using nickel to suppress the martensite start temperature [124]. They found that the the bainite and martensite start temperatures are suppressed as expected, this might be useful for design of steels to be produced by continuous cooling, however they also reported that coalescence of the bainite plates occurred since there was an excess of free energy available at the BS temperature.

The magnitude of the different strengthening mechanism in low temperature bainite can be calculated based on the characterisation of the microstructure. Steel of composition Fe-0.8C-1.6Si-2Mn-0.3Mo-1.33Cr-0.1V transformed at 200∘C results in carbide free microstructure with a bainite plate size between 50 and 100 nm. X–ray diffraction experiments described later in the thesis reveal a large supersaturation of carbon in the ferrite.

If a stress is applied to a polycrystal, dislocations will first move in a grain having a large critical resolved shear stress. However, as dislocations cannot in general cross a grain boundary, they will pile up at the boundary until the stress there is sufficient to generate slip in an adjacent grain. At this point, general plastic flow can occur, and the material is said to have yielded.

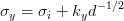

For equiaxed grains the yield stress σy is related to the grain size d by equation 1.5, the Hall–Petch equation [125, 126, 127],

| (1.5) |

where σi and ky are constants, σi is sometimes called the friction stress.

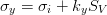

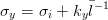

Rhines [128] suggested that the physically significant parameter is the inverse grain boundary area SV rather than the grain size, equation 1.6. Naylor [129] and then Daigne et al. [130] demonstrated the inverse linear relationship for laths and plates as occur in martensite and bainitic steels, equation 1.7.

| (1.6) |

| (1.7) |

The strength of mixed microstructures of bainite and martensite was investigated by Young and Bhadeshia [131], they explained that a peak strength can be achieved in mixed microstructures by varying the combination of martensite and bainite. They described the strength with the equation 1.8 due to Bhadeshia [132]. The model was able to reproduce the trends and absolute values of experimental data of Tomita and Okabayashi [133, 134]. The strength of martensite and bainite was factorised into a number of intrinsic components. Mixed microstructures of bainite and martensite can be stronger than either of the individual phases, Tomita and Okabayashi suggest this is by effectively refining the austenite grain size by the bainite sheaves [135]. The peak strength of mixed microstructures can be explained by the model to be due to increased carbon in martensite forming from enriched austenite. The contribution from bainite at small volume fractions was larger than expected, this was attributed to a plastic constraint effect which enhances the strength of the bainite. It was found that an additional term was needed to explain the strengthening at low volume fractions of bainite, equation 1.9.

| (1.8) |

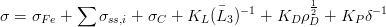

where KL, KP and KD are constants, σFe is the strength of pure annealed iron, σss,i is the solid solution strengthening due to substitutional solute i, σC is the solid solution strengthening due to carbon, 3 is a measure of the ferrite plate size, and ρD is the dislocation density, δ is the distance between carbide particles, and the strength of constrained bainite may be represented by the equation,

![′

σB ≈ σB[0.65exp (− 3.3Vb) + 0.998] ≤ σM](superbainite51x.png) | (1.9) |

where σB and σ′B represent the strength of constrained and unconstrained bainite respectively, σM is the strength of martensite, and V b is the volume fraction of bainite. For a mixture containing 0.5 volume fraction of bainite this will increase the strength of the bainite component by 12%, and with 0.8 volume fraction will give an increase of 4.5%.

Garcia-Mateo and Caballero [4] reported the results of mechanical testing and allocated the strengthening to contributions from the plate size and the dislocation density. Dislocation density was measured from the peak broadening in X–ray diffraction experiments and plate thickness measured using transmission electron microscopy. The reported contributions are shown in figure 1.23 and compared against the 0.2% yield strength and the ultimate tensile strength.

The strengthening contributions can also be calculated from equation 1.8 neglecting the effect of constraint, which for large volume fractions should account for around 4% increase according to equation 1.9. Using equation 1.8 allows calculation of the strength of the bainitic ferrite as a function of temperature, the result of which is shown in figure 1.24. It should be noted that from the previous results carbon supersaturation in the ferrite should be expected to make a large strengthening contribution, but has been omitted by Garcia-Mateo and Caballero.

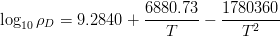

The dislocation density values reported by Garcia-Mateo et al. are in general agreement with the relationship proposed by Takahashi and Bhadeshia, as shown in figure 1.25. Takahashi and Bhadeshia showed the trend of increasing dislocation density with decreasing transformation temperature for both martensite and bainite, with a maximum dislocation density at around 350∘C [55]. Noting that the tendency for accumulation of dislocations by plastic deformation, and removal by recovery effects are both dependent largely on the transformation temperature they proposed the empirical equation 1.10. Dislocation density and therefore strength contribution is reasoned to be constant at lower temperature following Young and Bhadeshia [131]. For a given composition of bainitic steel the substitutional solute concentration in the ferrite is fixed, without precipitation of carbides the effect of transformation temperature will be via the grain size, dislocation density, and the carbon in the ferrite.

| (1.10) |

where ρD is the dislocation density, the length per meter cubed, and T is the absolute temperature in Kelvin.

The bainitic ferrite makes up only part of the microstructure, and this proportion increases with decreasing temperature, as volume fraction of ferrite increases as the temperature is decreased. This can be calculated by using thermodynamic calculation of the limiting T0 curve or can be empirically fitted to the volume fraction data reported by Garcia-Mateo et al..

Garcia-Mateo et al. [92] reported values of carbon content measured by X–ray along with plate thickness in alloy B in the temperature range 200–320∘C. The plate size as a function of temperature can be calculated as a function of temperature using an arbitrarily chosen function fit to the plate width data provided by Garcia-Mateo. This was found to be a linear relationship on a log–log plot of plate size against temperature. Fitting to a larger data set of all the values reported in the literature was not trivial, not only are their problems performing regression due to bias by outliers, but it also seems that there is disagreement between the results of the different authors [100, 137, 116, 103], as shown in figure 1.26. While the values do tend to converge as the temperature is decreased, at higher temperatures there are very different values for the different steels studied by the various investigators. It is probable that there are also composition effects which would need to be accounted for in a physical model. Composition effects on the plate size have been previously investigated by Singh and Bhadeshia [138], who created a neural network model to account for the effects due to the strength of austenite and the chemical driving force available for transformation. The model shows that increasing the strength of the austenite by 100 MPa can lead to a decrease of 0.2 μm, this is thought to be consistent with plate size being limited by plastic deformation induced during transformation. For purely elastic deformation of the plates, the opposite trend should be expected, increase of plate size with the increased driving force available at lower temperatures [139].

Factor | Strength Contribution | Ref. |

Fe |

| [140] |

C | 0.25wt% C × 3700 MPa/wt% | [141] |

C | (0.25wt% C)1∕2 × 1722.5 | [142] |

C | (0.25wt% C)1∕3 × 1171.3 | [143] |

Si | 1.6 wt% Si × 85 MPa/wt% | [141] |

Mn | 2 wt% Mn × 32 MPa/wt% | [141] |

Mo | 0.3 wt% Mo × 30 MPa/wt% | [141] |

Cr | 1.33 wt% Cr × -30 MPa/wt% | [141] |

V | 0.1 wt% V × 9 MPa/wt% | [140] |

Dislocations | 7.34 × 10−6 × |

|

Plate Size | 115 ×

exp | |

Cementite spacing | Not applicable |

|

Using a rule of mixtures with a linear weighting of the volume fraction, the yield strength of low–temperature bainitic steels can be calculated, as shown in table 1.10 and figure 1.27 were the calculation is for alloy B. To make the calculation, fitting to experimental data has been used, although in principle the calculation can be made more physical, it may be misleading to base calculation on thermodynamics unless the levels of carbon supersaturation in austenite and ferrite and the volume fractions match the experimental values, which is not yet the case. Instead a series of empirical approximations were made to the reported values of plate size, volume fraction, and compositions of the phases.

An arbitrary linear fit was used to include the relationship between the volume fraction of bainitic ferrite and temperature. As shown in figure 1.28 this better matches the experimental measurements than the calculation based on thermodynamic T0. Values reported between 200 and 300∘C are approximately linear, and lower than thermodynamic calculation of same. The strength of the retained austenite was estimated to be 640 MPa, calculated using empirical equation after Irvine et al. for the enriched composition but ignoring any grain size effects [144]. Extrapolation of yield stress data from higher temperature tests [145] using a function for the strength as a function of temperature [138] gives an estimated yield strength of around 500 MPa at room temperature for the composition before enrichment, and agreed with the calculated value using the function of Irvine et al..

As shown in the figure, accounting for the volume fraction of bainitic ferrite makes the calculated yield strength much more sensitive to the transformation temperature than before. Not only is the bainitic ferrite harder, but the larger volume fraction makes a larger contribution to the final strength. It is also apparent that the strength of the austenite can only make a minor contribution to the strength unless it can have comparable strength as the bainitic ferrite.

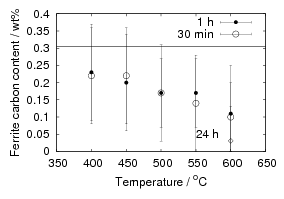

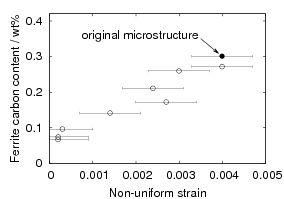

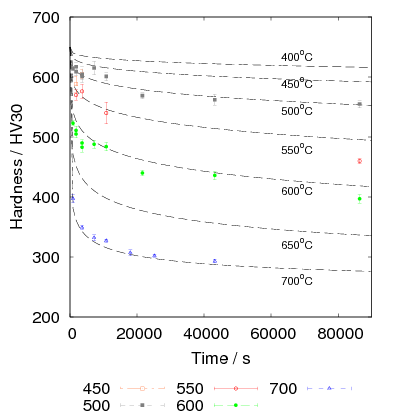

The calculated yield strength is much higher than the strength realised in the low–temperature bainitic steels. This may be due to incorrect calculation of the strength of the bainitic ferrite, it may be more appropriate to omit the effect of carbon as Caballero and Garcia-Mateo, and only consider strengthening by dislocations and plate size, this would be the case if the carbon trapping in the bainite is of a different character to the trapping in martensite. It may also be that the details of the calculation are overestimating each of the strengthening effects due to extrapolation from the range of previous results.